Patrick Edgeley is a Brighton & Hove-based screen printer creating bold, limited edition prints that celebrate hand-drawn typography, nostalgic imagery, and pop culture references. Strongly influenced by Americana, vintage signage, packaging, and mid-century design, his work blends graphic impact with a deep appreciation for visual storytelling.

With a background in graphic design, Patrick’s love for type and composition is evident in every piece. Each screen print is hand-pulled in small, carefully crafted editions and is available through this website, as well as selected galleries and exhibitions worldwide.

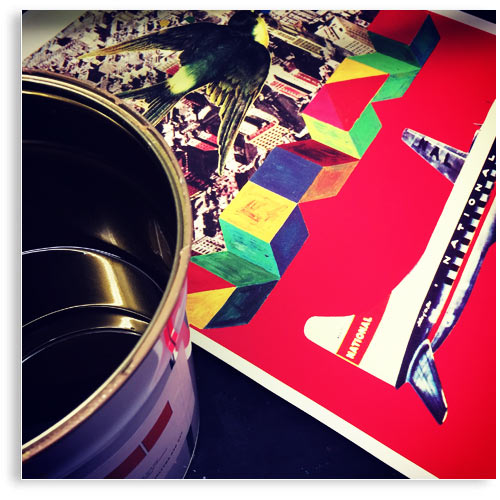

“In recent years, my work has evolved to incorporate collage techniques—layering vintage imagery with panels of colour to create balanced, visually engaging compositions. I’m continually inspired by 20th-century Americana—its optimistic take on space travel, futuristic gadgets, artificial flavours, and kitsch, colourful packaging.”

“Where I once leaned into naive, hand-drawn styles, I now use found imagery from the 1940s through to the 1980s. These elements are curated into thoughtful, often playful collages that are then transformed into hand-pulled silkscreen prints.”

The Process

Each print is made using traditional screen printing methods—an artisanal process dating back to 960 AD and refined over centuries. Popularised in Europe during the 18th and 19th centuries, screen printing remains a vital artistic technique, famously embraced by icons such as Eduardo Paolozzi, Peter Blake, Peter Phillips, and Andy Warhol.

“What I love most is the rhythm and challenge of the screen printing process. I’m constantly pushing boundaries—experimenting with colour, technique, and layout to see what’s possible. It can be painstaking and unpredictable, but those unexpected moments often lead to the most interesting results.”

“Unlike digital prints, each screen print carries slight variations—subtle shifts that make every piece unique. There’s a tactile quality and presence that only comes from printing by hand.”

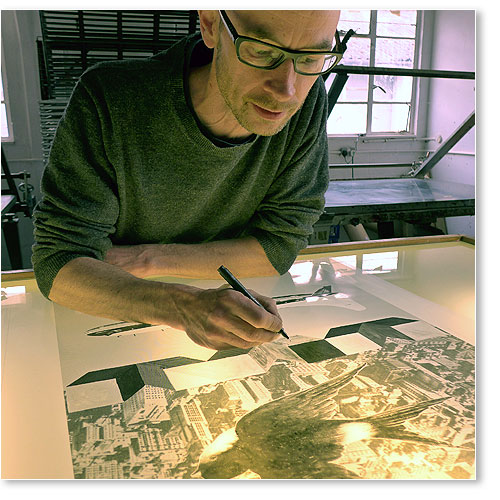

Artwork & positives

The screen printing process begins with preparing the artwork for print. Once the final design is complete, it is separated into individual colour layers—one for each colour that will appear in the finished print. This is known as colour separation and is a crucial step to ensure accurate registration during printing.

Each layer is then converted into a positive film, which is a black-and-clear image printed onto a transparent sheet—typically made from acetate. The black areas represent where ink will pass through the screen, while the transparent areas will block light during exposure. These films are created using either an inkjet printer with high-density black ink or a laser printer, depending on the level of detail required.

Accuracy is key here: all layers must align precisely in the final print. To ensure this, registration marks are included on each film. These allow for exact positioning of each screen on the print bed, maintaining alignment across multiple colour passes.

Once the positives are complete, they’re ready to be used in the next step—screen exposure, where each film is used to create a stencil on a separate screen.

This stage combines graphic design, technical accuracy, and a deep understanding of how colour interacts through layering—a blend of digital preparation and traditional craftsmanship.

Coating the screen

Once the positive films are ready, the next step is to prepare the screens by applying a light-sensitive emulsion. This emulsion acts much like photographic film—it reacts to light exposure and forms the stencil that allows ink to pass through in specific areas.

A photosensitive liquid emulsion is evenly applied to both sides of a clean, degreased mesh screen using a coating trough. The aim is to create a smooth, thin, and even layer across the entire surface. Consistency at this stage is critical: an uneven coat can result in poor image resolution or patchy stencils.

After coating, the screens are placed in a light-safe environment—usually a dark room or a drying cabinet—to allow the emulsion to fully dry and cure. This is a delicate process; any premature exposure to light can compromise the stencil and ruin the screen.

“Much like developing film in a darkroom, coating and curing the screen is a foundational part of the silkscreen process. It sets the stage for accurate exposure and, ultimately, the clarity of your final print.”

Once dry, the screens are ready for exposure using the positive films, where the actual stencil is formed through controlled light exposure.

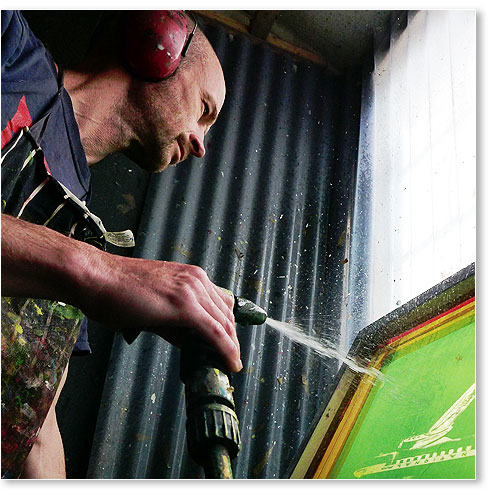

Exposing & washing out the screen

With the emulsion-coated screen fully dried, the next step is to transfer the artwork onto the screen using light exposure.

The positive film is carefully positioned on the exposure unit, directly against the emulsion-coated side of the screen. The screen is then exposed to a powerful UV light source for a precise amount of time. This light hardens, or “cures,” the emulsion wherever it is exposed—essentially fixing it to the mesh.

However, the black areas of the positive film (representing your artwork or image) block the UV light. As a result, the emulsion in these areas remains soft and unexposed.

Once exposure is complete, the screen is taken to a washout booth, where it is gently rinsed with water. The unexposed emulsion dissolves and washes away, leaving behind a clean, open mesh in the exact shape of the design. The fully cured emulsion remains intact, blocking ink from passing through during printing.

“This step is like developing a photograph—it’s where the image truly begins to emerge. The precision of the exposure and the care taken during washout directly affect the sharpness and detail of the final print.”

After washout, the screen is left to dry completely before moving on to setup and printing. At this point, it’s a fully prepared stencil—ready to be used in the printing process.

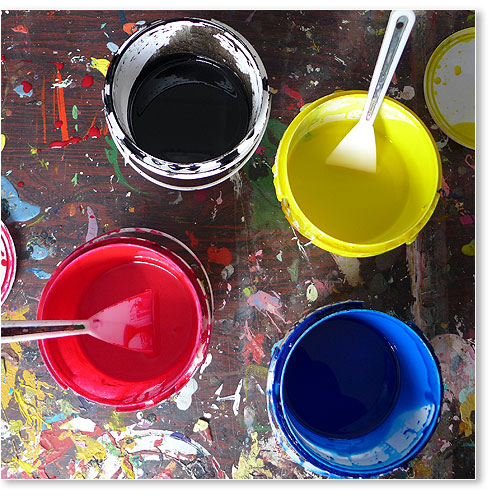

Mixing colours

One of the most enjoyable parts of the screen printing process for me is mixing colours. It’s where creativity meets chemistry, and it plays a huge role in the final character of a print.

Screen printing inks are typically mixed with a printing medium to slow down drying time, which helps prevent the ink from curing too quickly and clogging the mesh—especially important on warmer days or during longer print runs. This additive keeps the ink workable on the screen and ensures smooth, consistent pulls.

I primarily work with acrylic-based inks, which are water-soluble, fast-drying, and widely used in contemporary screen printing. There are many variations on the market, each offering slightly different finishes and behaviours. As a general rule, higher-quality inks contain more pigment, resulting in deeper, more vibrant colours and better opacity.

“The richness of colour is something I really pay attention to—especially when layering multiple tones. Getting that mix just right is incredibly satisfying and can really transform a piece.”

While acrylics are my go-to, I occasionally incorporate oil-based inks for specific effects—particularly when I want a gloss spot colour or a finish that acrylics can’t quite achieve. Oil-based inks tend to deliver more saturated, lustrous results, but they also require more intensive cleaning and aren’t as environmentally friendly.

“I use oils sparingly, usually just for accent areas. Acrylics have come a long way, but in my experience, they still don’t quite match the gloss and richness oil can bring to certain details.”

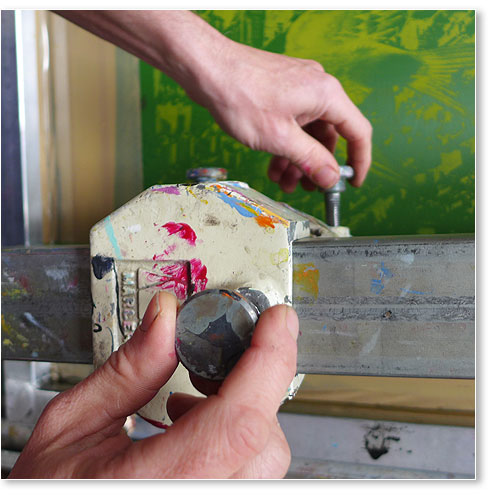

Printing & Registration

With the screen exposed, washed out, and fully dry, it’s ready to be mounted onto the print bed. Precise registration is critical at this stage—especially when working with multi-colour prints. Each screen must align perfectly with the others to ensure the final image comes together as intended.

To achieve this, I use a combination of registration tabs, guides, and marks—some built into the artwork and others manually placed on the print bed. The paper is aligned to these marks with care, allowing for consistent placement with every pull.

Depending on the complexity of the design, this process may be repeated with several screens—each one corresponding to a different colour layer. Registration is adjusted between each layer to maintain alignment across the full edition.

“Getting the registration just right is often one of the most demanding parts of screen printing—but also one of the most rewarding. When every layer snaps perfectly into place, the final image has a richness and clarity that digital processes simply can’t replicate.”

Inking & Pulling the Print

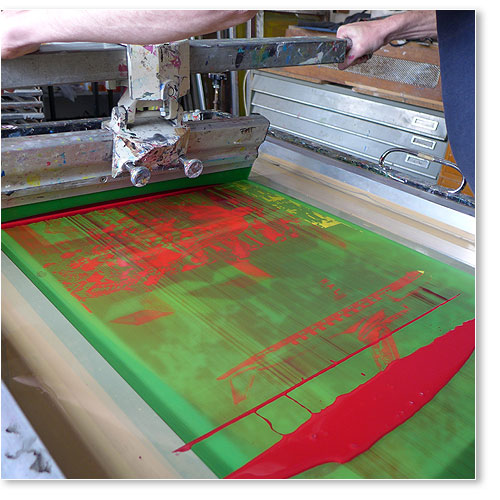

Once registered, the screen is lowered onto the paper, and the actual printing begins. A measured amount of screen printing ink is applied to the top of the screen and drawn across the stencil using a squeegee. With firm, even pressure, the ink is pulled through the open mesh areas and onto the paper beneath.

This process is repeated for each print in the edition, and for each colour layer—cleaning and drying the screen between colours as needed.

Every pull of the squeegee is done by hand, giving each print subtle variations in ink texture and tone. It’s this handmade quality that sets screen prints apart, making each one slightly unique—even within a limited edition run.

“There’s a rhythm to printing—loading the screen, pulling the squeegee, lifting to reveal the print beneath. It’s a physical, meditative process that feels more like painting than pushing a button. It’s also where all the previous steps come together, and the image truly comes to life.”

Once printed, the paper is set aside to dry completely, often on drying racks to prevent smudging or sticking. Only after all layers are printed and fully dried is the edition complete—signed, numbered, and ready for collectors.

Closing Thoughts

Screen printing is a blend of precision and unpredictability, tradition and experimentation. From preparing the artwork to pulling the final print, every step is done by hand—introducing subtle variations and a depth of character that can’t be replicated by digital methods.

What might seem like a simple process is in fact a craft rooted in patience, timing, and technical skill. Each piece reflects hours of preparation, problem-solving, and hands-on work—making every print not just a reproduction, but an original in its own right.

“For me, screen printing is more than a technique—it’s a rhythm, a ritual, and a way of bringing design to life through ink, mesh, and motion.”